15 Jul Recap/Report: FDRA’s Factory Training Workshops in China (June 25/27)

by FDRA’s Andy Polk

FDRA held a Product Safety and Environment (PSE) training workshop in Dongguan, China on June 25th and a Responsible Footwear Forum (RFF) workshop in Putian, China on June 27th. Combined attendance at these events reached nearly 100. Both events included interactive discussions and a high level of participation, with the RFF workshop using new and innovative ways to teach attendees how to manage factory performance by better understanding the business relationships between different areas of the factory.

PSE Dongguan Highlights:

The PSE workshop in Dongguan began with FDRA’s Factory Survey. This created a large discussion as six different factory mangers shared how their factories measured up against various sections of the survey – including how they address worker grievances, how they recruit and retain skilled workers, and challenges with brand expectations. The workshop continued by covering Prop 65 and Washington State product safety regulations, allowing attendees to ask questions. For the first time, FDRA translated into Chinese and distributed its “Managing Chemicals in Footwear” (RSL) report. This created a robust discussion about chemicals in footwear and how factories can better use testing labs to ensure they are not utilizing forbidden chemicals. Product quality and Consumer Product Safety Commission (CPSC) changes were also covered as attendees were taken through footwear recall case studies. Lastly, Mr. Tan, Dongguan’s environmental official, covered changes to China’s product safety requirements. Take away: Many of the attendees I spoke with enjoyed the ability to discuss how their factories measured up to the FDRA factory survey. They spoke about how the new RSL report would greatly help their internal management better understand product safety requirements related to chemical usage.

RFF Putian Highlights:

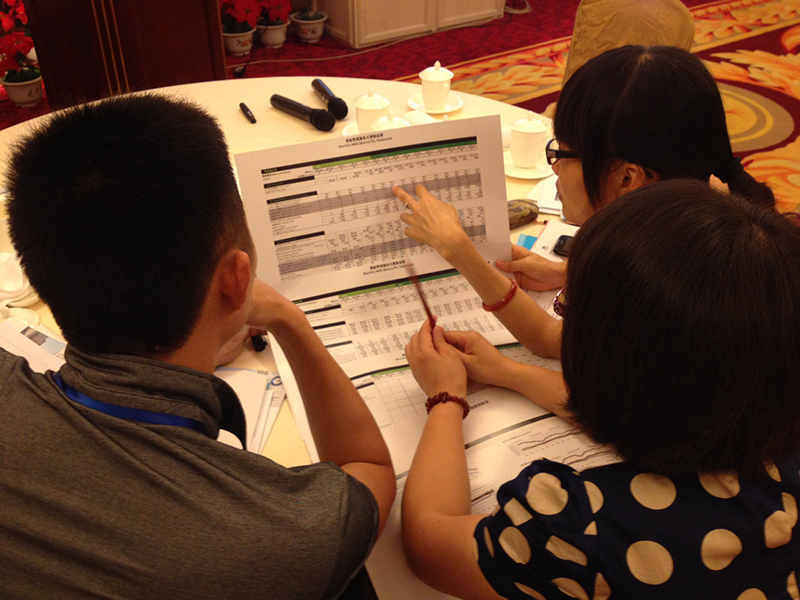

Like the PSE workshop, RFF also opened with a very vibrant discussion of FDRA’s Factory Survey. Due to recent factory collapses and fires in the Asia-Pacific region, FDRA dedicated over an hour to factory fire and safety related information. This included covering the top 10 safety issues found in factories and how to address them. This also included a discussion on structural safety, regulating hazardous materials at the factory, protecting against electrical fires, ensuring factory employees have access to fire extinguishers and know fire exits, among other issues. Attendees were very attentive to the safety presentation and took many notes. The afternoon section focused on how to better use data, metrics, and KPIs to help understand challenges, set goals and measure progress. Attendees had a chance to setup KPIs and action steps to address and meet company goals such as reducing worker turnover, increasing worker output, and reducing worker injuries. The second group exercise focused on introducing the concepts of factory data analysis. The data came from real factory data and was pulled from different areas of the factory such as Production, Human Resources, and Health and Safety. The groups were tasked with analyzing a year’s worth of data to try and establish correlations between changes in the factory’s workforce (turnover, injuries, new workers, etc.) and how this affected production and units produced. This turned out to be quite a stimulating exercise, as many attendees had never looked at factory information in this manner. The focus was less on compliance and more in impacting the factory’s overall business. Take away: The factory fire and safety really engaged attendees. They asked questions and took notes throughout the presentation. There was a clear hunger to understand and address hazards. The afternoon presented a new and innovative way to get managers to think about and solve factory challenges. Asking them to discuss issues among themselves, rather than just go through power points, allowed them to think more deeply about the challenges that factory’s face that can ultimately lead to compliance issues. I personally think this laid the foundation for new skills and confidence to think about factory challenges more critically and may help them work smarter at solving these challenges.

Overall the workshops were a success. Attendees were very attentive and participated. Feedback was good. FDRA is holding these workshops again in November to train more factory managers. Based on the results from these workshops it is clear there is a great need and benefit for US Footwear companies and brands to push their factories to send participants.

To see all of FDRA’s workshop photos please visit: http://www.flickr.com/photos/fdra/